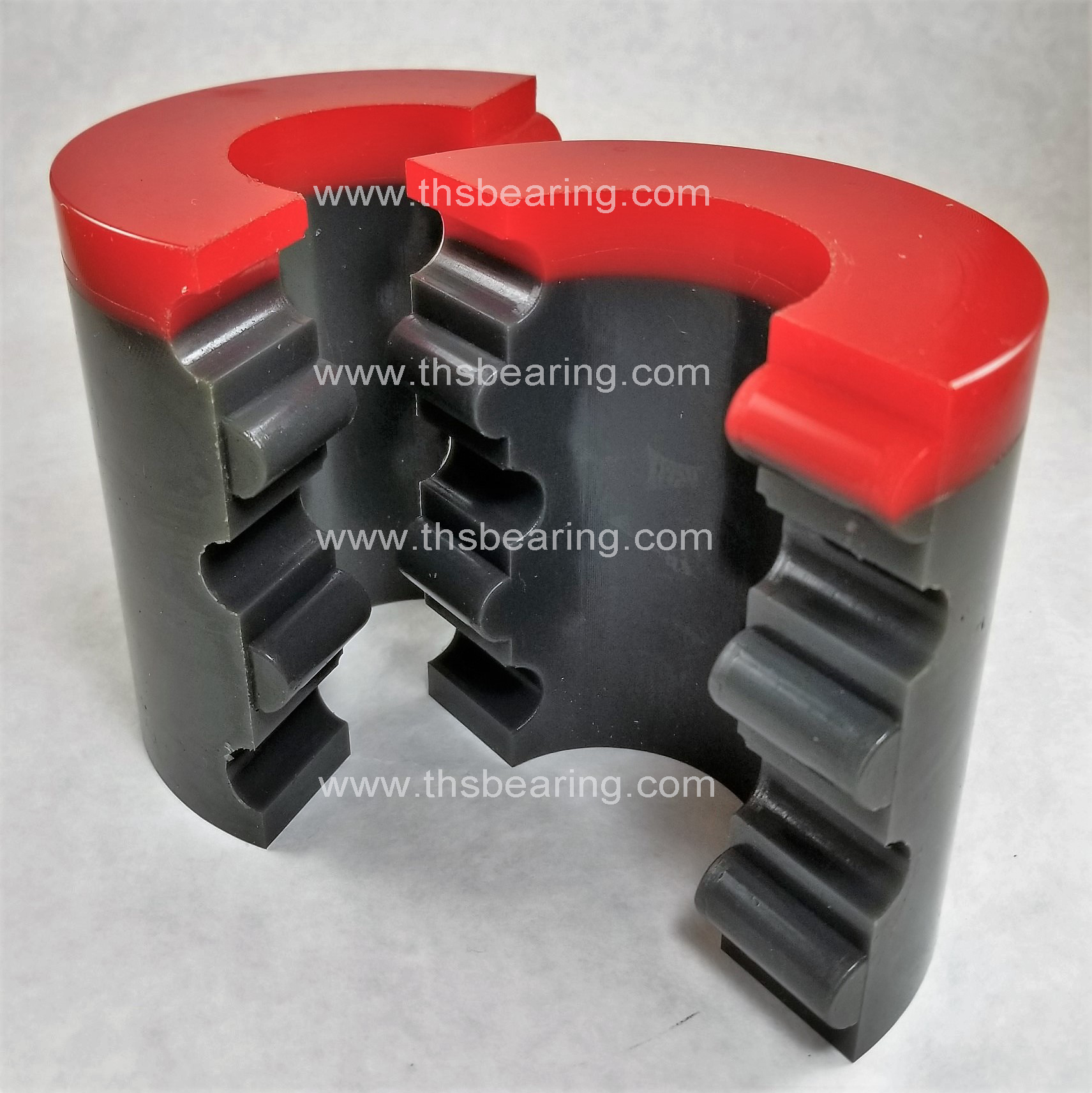

3.06 4.06 Coil tubing stripper rubbers seal

3.06 4.06 Coil tubing stripper rubbers sealCoil tubing stripper rubbers Non-Extrusion Rings

Stripper rubber seals are widely used in pack-off for the coiled tubing industry. Their reliability and low maintenance have been proven in many field operations. stripper rubber is designed for the working pressure range of 1000 to 8000psi. It is manufactured from the finest urethane compounds with superior abrasion resistance and high mechanical performance. Operating temperature ranges from 20°F to 230°F. Coil Tubing Stripper is your best cost effective pack off. Coil Tubing Pack Off Rubber is available in the following sizes: OD 3.06″ with ID option 1″, 1 1/4″, 1 1/2″, 1 3/4″,2″ and 2 3/8″ OD 4.06″ with ID option 1 1/4″, 1 1/2″, 1 3/4″, 2″, 2 3/8″, 2 5/8″ and 2 7/8″When it comes to petroleum equipment pipelines, stripper rubbers play a crucial role. These components, known as “stripper rubbers,” are essential for efficiently stripping liquids and solids within pipelines. In the processes of petroleum extraction and transportation, pipelines require frequent cleaning and maintenance to ensure efficient operation and safety. Here’s a detailed overview of these critical components:

1. Function and Purpose

Stripper rubbers are designed for specific locations within pipelines, typically at joints or bends. Their primary function is to strip residual liquids and particulates from the pipeline through friction and elastic force, ensuring cleanliness and smooth operation inside the pipeline. In the petroleum industry, contaminants inside pipelines can include viscous oils, deposited solid particles, and other substances that may affect fluid transport efficiency and safety.

2. Structure and Materials

These rubber components are typically made from specialized high-strength rubber materials to ensure durability and stability under high pressures and harsh environments. High-quality stripper rubbers can withstand long-term use and frequent cleaning processes while maintaining effective stripping performance.

3. Applications

At petroleum extraction sites, pipeline systems often require cleaning and maintenance to remove deposits and impurities, maintaining efficient fluid transmission. Stripper rubbers facilitate these tasks with their unique design and material properties, reducing operational complexity and time costs during cleaning processes.

4. Technological Innovations and Developments

With advancements in technology and a continual pursuit of efficiency, the design and material selection of stripper rubbers are evolving and improving. The application of new materials and improvements in manufacturing processes enable stripper rubbers to perform excellently under broader operating conditions, thereby enhancing efficiency and reliability throughout the petroleum pipeline industry.

Conclusion

In conclusion, as an indispensable part of petroleum equipment pipelines, stripper rubbers not only play a crucial role in pipeline operation and cleanliness but also contribute significantly to technological innovation and development. By continuously optimizing their design and material selection, stripper rubbers are poised to provide more efficient and reliable solutions for the petroleum industry.

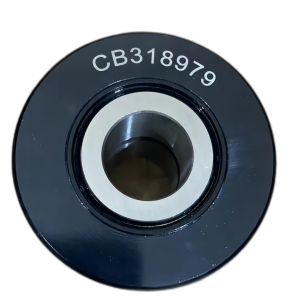

Needle bearing,Full Complement Bearings,Gripper blocks coiled tubing,Auto Bearing,coiled tubing injector chains,Cam Follower,Gear Pump Bearings,Textile Machine Bearing,

Needle bearing,Full Complement Bearings,Gripper blocks coiled tubing,Auto Bearing,coiled tubing injector chains,Cam Follower,Gear Pump Bearings,Textile Machine Bearing,

Dear gents,

could you please send your best quotation for 50pcs of 1 1/2 inch stripper seal kit please.

Thanks and best regards

2024-10-31下午10:03

Dear

please contact our agency phone:+ 213 6******30 he will serve you ,thank you!

2024-11-01上午9:40